Testing capabilities for feed bitumen and PMB, emulsions and cutbacks products:

Feed Bitumen binders: ASTM, AASHTO and CEN Penetration, viscosity and PG grades.

PMB Binders: ASTM, AASHTO PG and PG++ grades, CEN PMB Grades and other international specifications.

Modified Bitumen such as Crumb Rubber Modified Bitumen to Arizona specifications and Multigrade Bitumen to international specifications.

Emulsions and Cutbacks: ASTM, AASHTO, CEN Grades and other international specifications.

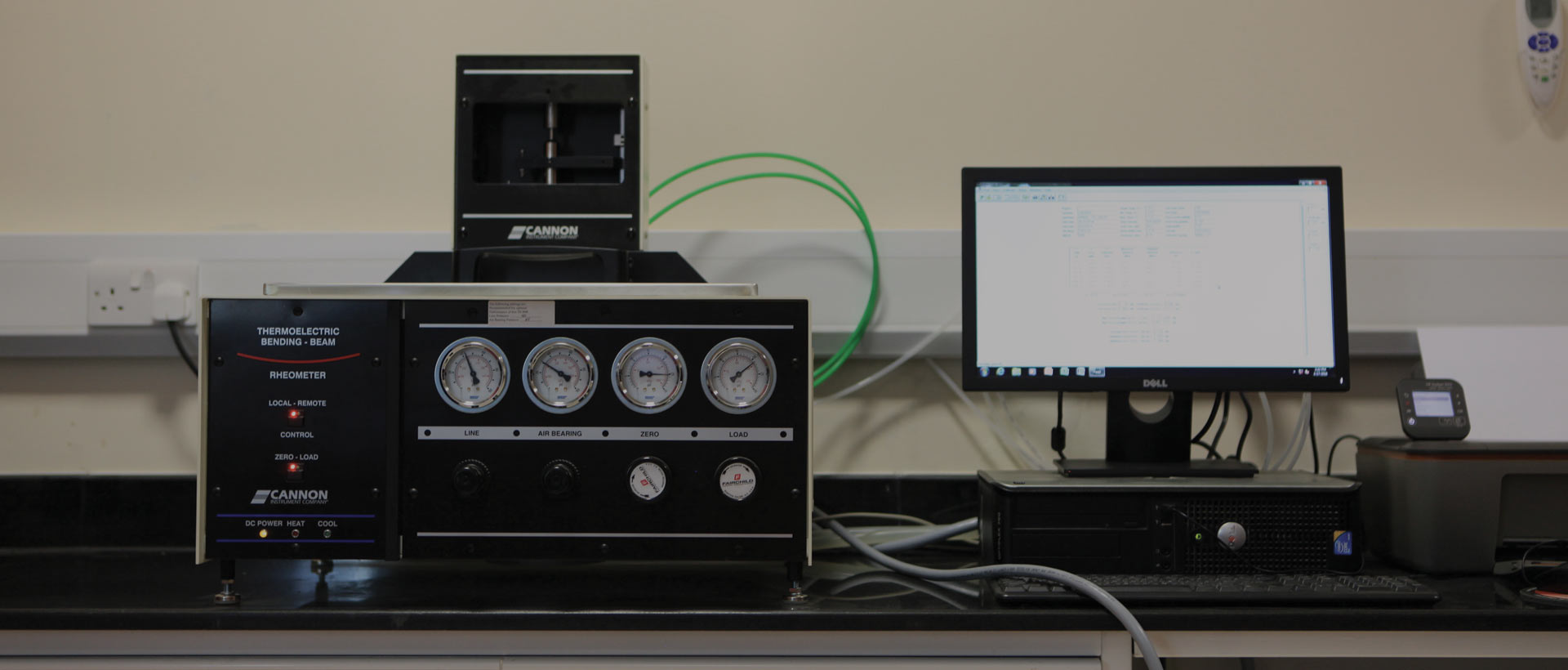

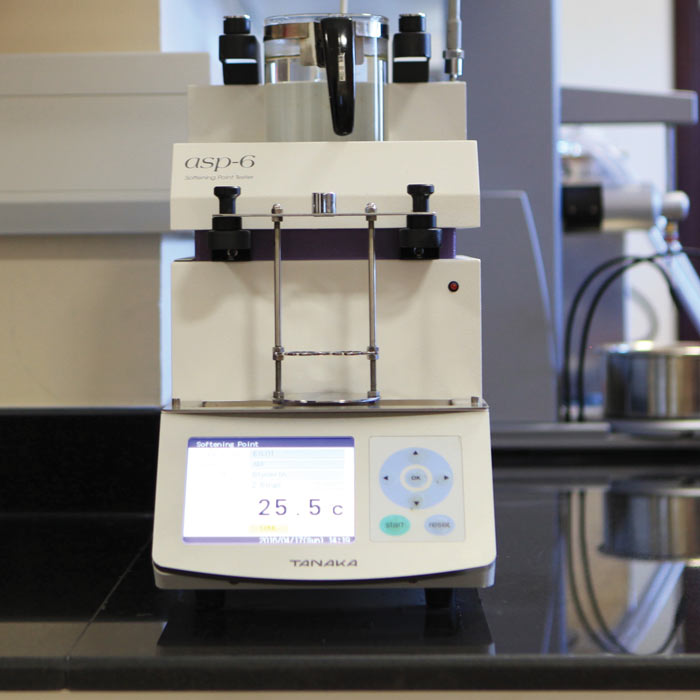

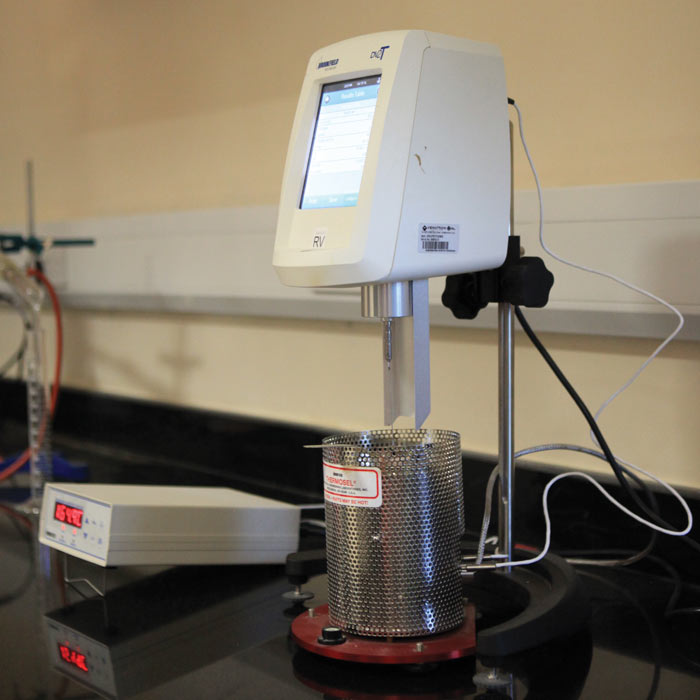

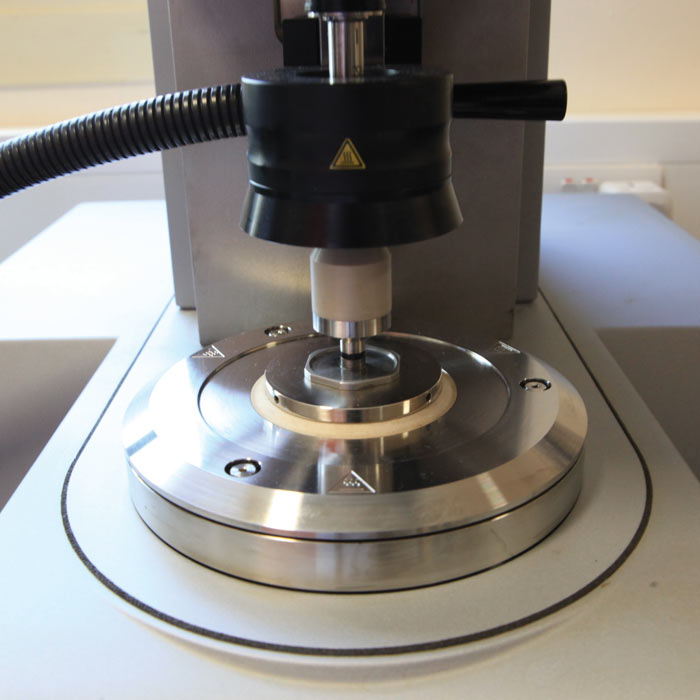

The test equipment includes high end Dynamic Shear rheometer, Bending Beam Rheometer, Brookfield Viscometer, kinematic and vacuum capillary viscometers, TFOT, RTFOT, and PAV units for durability, automatic Penetrometer, automatic Ring and Ball Tester, ductility, elastic recovery and forced ductility measuring device amongst others.

Our R&D station at UAE has several lab and pilot scale mixers, reactor and separation systems for formulation developments of advanced bituminous binders.

With our technical partnership programs with international laboratories, Elrich has wider access to Binder and Asphalt development and characterization laboratories at MARC-USA, Asphalt Institute USA amongst many others local partner institutes and centres at Universities and international commercial laboratories.

Elrich offers full transparency to our PMB project customers in terms of sources and stoichiometry of base bitumen and polymers.

Elrich presents a strong Quality Assurance mechanism through independent AASHTO / AMRL / ISO17025 accredited laboratories in USA and Europe, and witness testing protocols at our in-house accredited laboratory for our customers, project consultants and prestigious clients. Quality and Quantity COC services are available through recognized international inspection agencies upon request.

Successful field applications of Modified Bitumen and speciality emulsion binders require technical support services to meet the expectations

of airport, and highway pavement clients. Elrich technical services encompass the areas of laboratory mixture design, review of specifications and client submittals, asphalt performance testing such as Wheel Tracking Rut Tester, Fatigue testing, assistance to the customers in meetings with Consultants and Clients in the process of seeking approvals, mixing and compaction operations, field paving, troubleshooting, diagnostics for pavement failure analysis amongst others.